At WOKA, our commitment to precision is the foundation of our expertise in mould construction. We are not your average injection mold maker. Prototype molds or even precision molds, our on-site mold making department sets us apart, allowing us to reduce turnaround times and maximize productivity. Our ultimate goal is to deliver superior performance: maximum throughput, shortest cycle times and longer mold life, all through a seamless process.

The DFM Report: Optimizing Mold Design for Efficiency

Our commitment to precision extends to the very beginning of the process. The Mold Design for Manufacturing (DFM) Report is a comprehensive analysis that focuses on optimizing product manufacturing efficiency, quality, and cost-effectiveness. We delve into design considerations, potential challenges, and recommendations to ensure the production of high-quality components.

Moldflow Analysis: Simulating Success

Moldflow analysis involves creating a virtual model that replicates the mould’s geometry, the plastic material, and various process parameters. By simulating the entire injection molding cycle, we gain insights into how temperature, pressure, cooling rates, material properties, and mold design influence the final product’s quality and consistency.

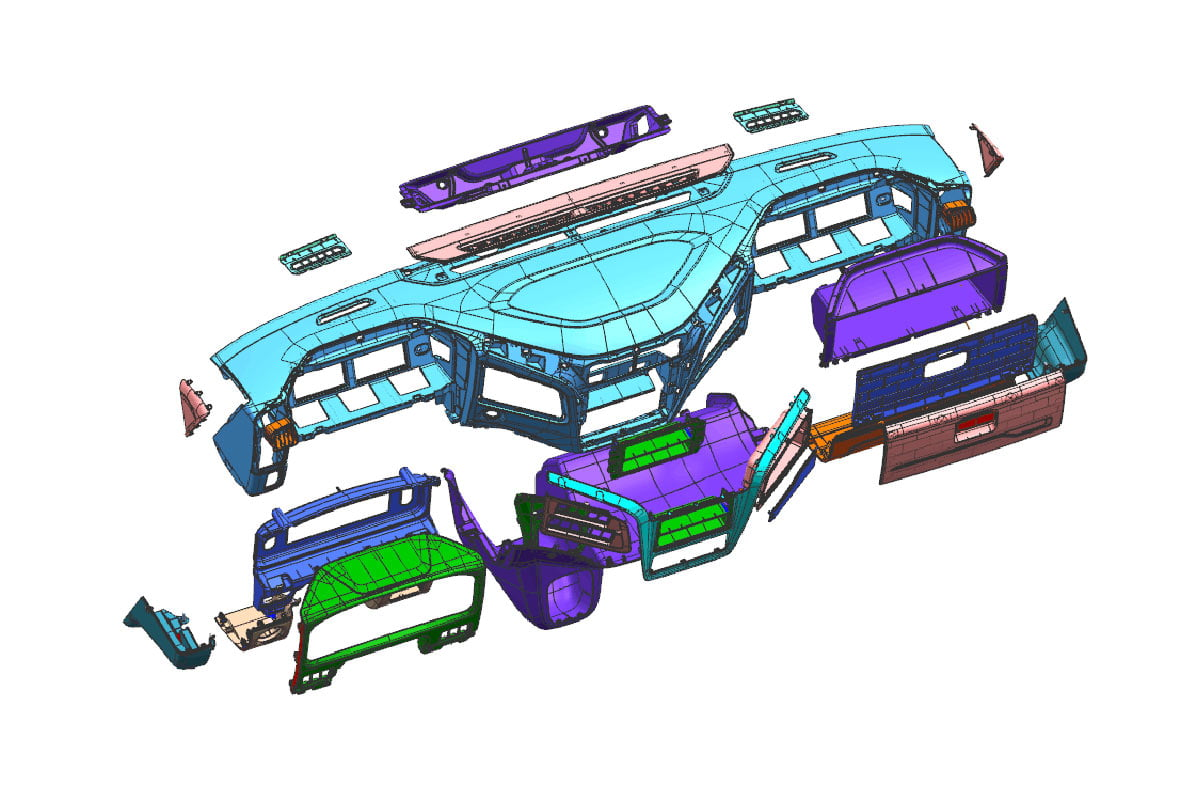

Precision in Mold Design

Precision mold design is the perfect combination of accuracy and creativity. It involves the fine planning and engineering of a three-dimensional mold cavity, usually made of a durable material such as steel or aluminum. It is in this mold cavity that molten materials such as plastic, metal or rubber are injected or poured. Design accuracy plays a pivotal role in determining the final dimensions, surface finish, structural integrity and overall quality of the product.

Injection Molding: State-of-the-Art Manufacturing Facility

WOKA’s manufacturing facility is equipped with 24 injection molding machines, ranging from 55 to 650 tons. These precision-engineered presses are known for their outstanding precision, high quality, dynamic responses, and industry-leading dry cycle times. To ensure efficiency, we employ a computerized material distribution system and have on-site silo storage of resin. Our expertise extends to running various resins, from commodity to engineered grades, high-temperature to filled materials.

The Power of Automation

Efficiency is at the heart of our operations. We’re dedicated to enhancing productivity through automation. Our presses operate in automatic mode wherever possible, and parts are removed from injection moulds by robotics. This dedication to automation results in a reliable, efficient, and cost-effective manufacturing system.

Conclusion

WOKA is not just a mould manufacturer; we’re your trusted partner in precision mould and prototype mold manufacturing. With a commitment to precision that runs through every phase, we’ve set new standards in the industry. Choose us as your partner and experience precision that goes beyond the ordinary.