Steps to work with us.

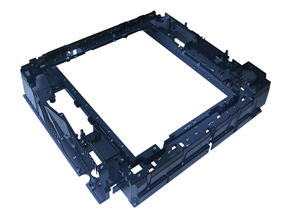

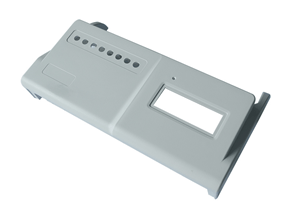

Medical Machine Housing

In the rapidly evolving landscape of modern healthcare, medical machinery has become synonymous with precision, efficiency, and reliability. Behind the scenes, the plastic injection mold industry plays a pivotal role in shaping the exterior of these cutting-edge medical devices. Welcome to the realm of Medical Machine Housing in the plastic injection mold industry, where innovation meets meticulous engineering.

The process begins with selecting high-performance medical-grade plastics for their ability to withstand harsh environmental conditions, sterilization processes, and repeated usage. Injection molding, a precision-driven technique, transforms these raw materials into housing structures with intricate geometries, uniform wall thickness, and consistent quality. This approach ensures that medical machinery remains functional and visually appealing while maintaining high accuracy and reliability.

Steps to work with us.

Steps to work with us.

Steps to work with us.

Steps to work with us.

Copyright © 2022. SHENZHEN WOKA MOLDING TECHNOLOGY CO.,LTD. All rights reserved.