Steps to work with us.

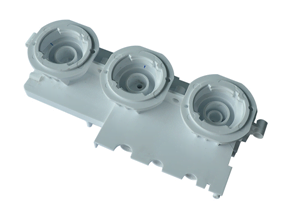

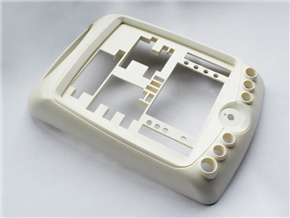

Medical Device Handle Housing

Material Integrity: Constructed from high-quality medical-grade polymers, the handle housing ensures biocompatibility, chemical resistance, and adherence to stringent regulatory standards. This choice of material guarantees that the housing is non-reactive with drugs, disinfectants, and bodily fluids, safeguarding both the patient and the healthcare provider.

Precision Engineering: The plastic injection molding process guarantees precision in replicating the housing design's intricate details and complex geometries. This precision ensures consistent quality across each manufactured unit, meeting the exacting standards of the medical industry.

Regulatory Compliance: Committed to patient safety and healthcare regulations, the medical device handle housing adheres to industry standards, including ISO 13485 and FDA guidelines. This ensures that the housing contributes positively to the safety and efficacy of the medical devices it enhances.

Steps to work with us.

Steps to work with us.

Steps to work with us.

Copyright © 2022. SHENZHEN WOKA MOLDING TECHNOLOGY CO.,LTD. All rights reserved.