Being one of the leading custom plastic mold manufacturers for years, WOKA can provide various moulding products with the advanced molding process. Check our following bumper mould process and learn more about us.

Prototyping Stage:

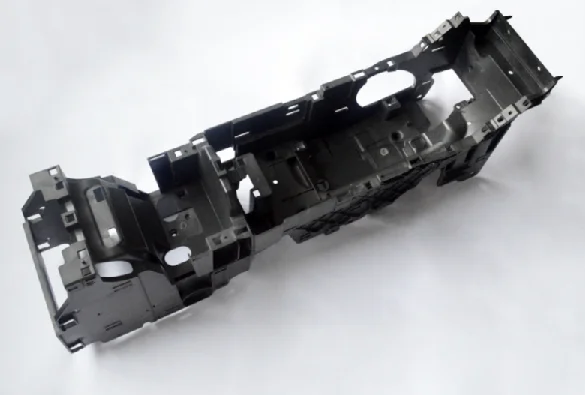

Tooling and Manufacturing:

Craftsmanship Beyond Compare:

WOKA recognizes that a bumper serves as more than just a protective shield; it embodies the vehicle's identity and safety. Leveraging two decades of expertise in plastic mold manufacturing, our engineers and artisans meticulously craft each bumper mould to meet exacting standards. Attention to detail is paramount, guaranteeing flawless curves, contours, and finishes that enhance your vehicle's aesthetics and performance.

Embracing Cutting-Edge Technology:

Following Steps to Work with Us.

Steps to work with us.

Steps to work with us.

Steps to work with us.

Steps to work with us.

Copyright © 2022. SHENZHEN WOKA MOLDING TECHNOLOGY CO.,LTD. All rights reserved.