Steps to work with us.

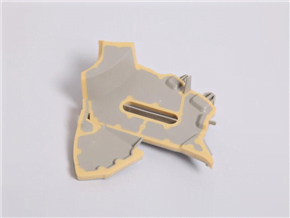

2K molding

2K Molding is a sophisticated manufacturing process that involves injecting two different materials into a single mold, creating a multi-component, multi-color, or multi-material product in a single operation. This process is driven by specialized injection molding machines equipped with dual barrels and nozzles, each capable of injecting distinct materials. The result is a product with enhanced functionality, improved aesthetics, and reduced assembly requirements.

At the heart of 2K molding lies an unparalleled level of precision. The process enables the creation of intricate designs and complex geometries that were previously unattainable using traditional injection molding techniques. This precision extends to over-molding, where a second material is applied onto the first to encapsulate, protect, or enhance specific features of the product. This reduces assembly steps and ensures a higher degree of sealing, structural integrity, and performance.

The versatility of 2K molding transcends industry boundaries, making it a game-changer across sectors such as automotive, electronics, medical devices, consumer goods, and more. In the automotive sector, for instance, the process can seamlessly integrate both rigid and elastomeric materials to create parts that provide exceptional comfort, durability, and safety.

Steps to work with us.

Steps to work with us.

Steps to work with us.

Copyright © 2022. SHENZHEN WOKA MOLDING TECHNOLOGY CO.,LTD. All rights reserved.